Technical Activities

Automatic Sanitization for transportation industry

Introduction

In light of the recent events related to the spreading of the COVID-19 epidemic, one of the measures that all railway and metropolitan transport operators are facing concerns the sound public health management and the routine indoor spaces cleaning, disinfection and sanitizing of common areas.

As far as the latter is concerned, AYES is committed to render assistance and provide concrete guidelines for defining effectiveness, development and deployment suitable systems capable of performing sanitizing tasks proficiently.

The measures to cope with virus

According to the Italian National Institute of Health COVID 19 Report n. 25 /2020 of 05.15.2020, the main measures taken into consideration are:

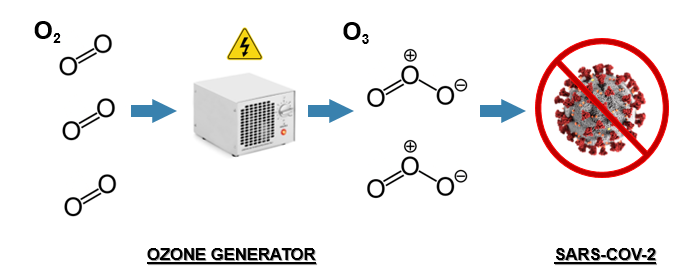

- Treatment with ozone;

- Treatment with UV;

- Treatment with vaporized hydrogen peroxide;

The ozone is the triatomic molecule of Oxygen equipped with strong oxidizing power (unspecific mechanism of action), harmful to biological membranes including viruses and bacteria. Recent studies support the high effectiveness of this technique to sanitize places and surfaces, with high performances to reduce the bacterial load and viral inactivation.

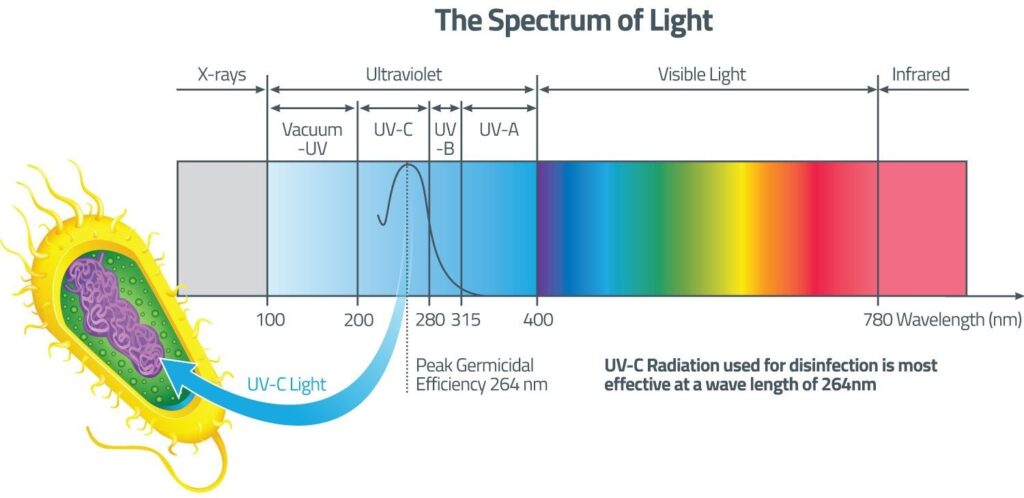

Typically, ultraviolet (UV) rays, such as germicidal lamps in sterilization systems, have dominant emission around 253nm wavelength.

UV-C radiation has the ability to modify the DNA or RNA of microorganisms preventing them from reproducing and therefore being harmful. Generally, the components with wavelengths shorter than 250nm are filtered in order to prevent any risk of ozone production. In this case, the UV lamp is called “ozone free”.

The hydrogen peroxide is a biocidal active substance approved in accordance with BPR (Biocidal Products Regulation).

The hydrogen peroxide mechanism of action relies on its oxidizing properties and denatured essential components (lipid membrane, protein and nucleic acid).

The antimicrobial activity comes from the creation of strong oxidant such as hydroxyl radicals and “singlet” oxygen, responsible for the biocidal activity. In parallel, these reactive oxygen species cause irreversible damage to cellular compounds and DNA.

AYES approach

During lockdown period, AYES has built an ad hoc R&D taskforce. This dedicated team is investing its efforts focusing in research on automatic sanitizing techniques.

Leveraging our knowledge and consolidate experience in the transport industry, we are supporting our customers to find the right application of the safety management. Based on the cost-effective and feasibility criteria, the aim is to maximize the utilization of the subsystem already implemented with the minimal impact on the retrofit process. The integration of this subsystem will set up one unique system: simple and automatic, capable of implementing the right sanitizing process of the surfaces and common areas.

Automatic sanitization systems

The role of an automatic system can be summarized in the following points:

- The system can be activated remotely or even from the driver’s desk. The risk of undue activation will be evaluated and mitigated with the help of HW as timed relay which arrest the system after the time set for disinfection;

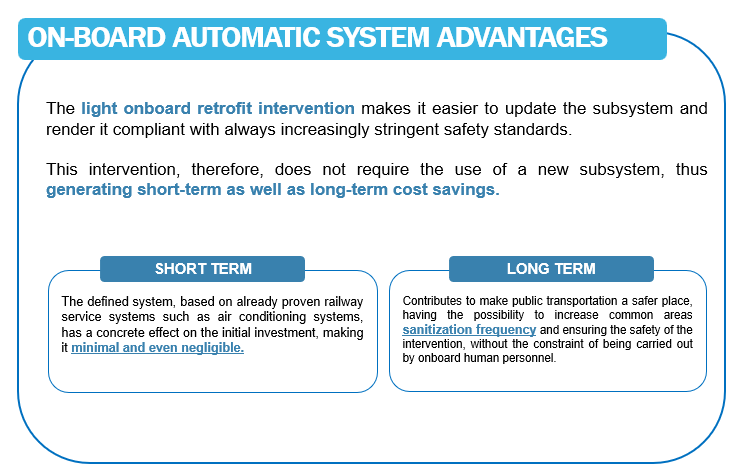

- The light onboard retrofit intervention makes the subsystem update easier and compliant with more increasing and stringent safety standards. This intervention, therefore, does not require the use of a new subsystem, thus generating short as well as long-term cost savings.

– Short-term advantages are represented by the minimal and negligible initial investment;

– Long-term ones referring to make the public transportation a safer place, increasing common areas sanitization frequency and ensuring the safety of the intervention, without the constraint of being carried out by onboard human personnel.

Regarding the exposure time of Sanitization, two possible ways have been evaluated:

- Light: could be performed several times a day, with the capacity to kill bacteria;

- Regular: takes more time and can be performed for example during the evening, with the capacity to deactivate virus;

Capillarity of sanitization agents spreading is fundamental, so some special cases have to be taken into account. It is the case for „blind spots“ (e.g. toilets), not directly reachable. These cases will have to be managed ad hoc.

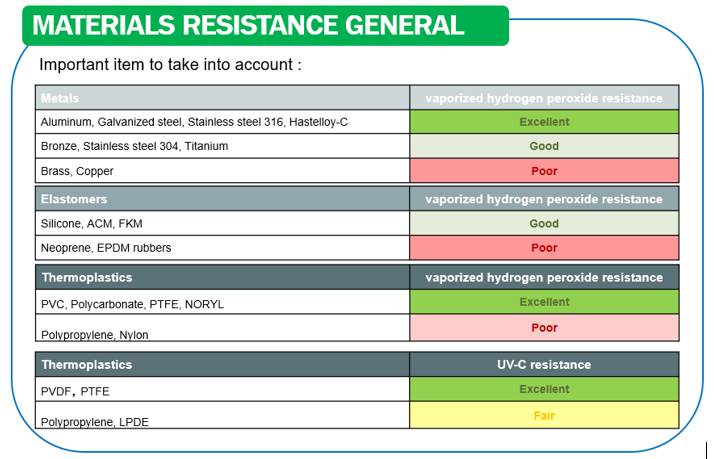

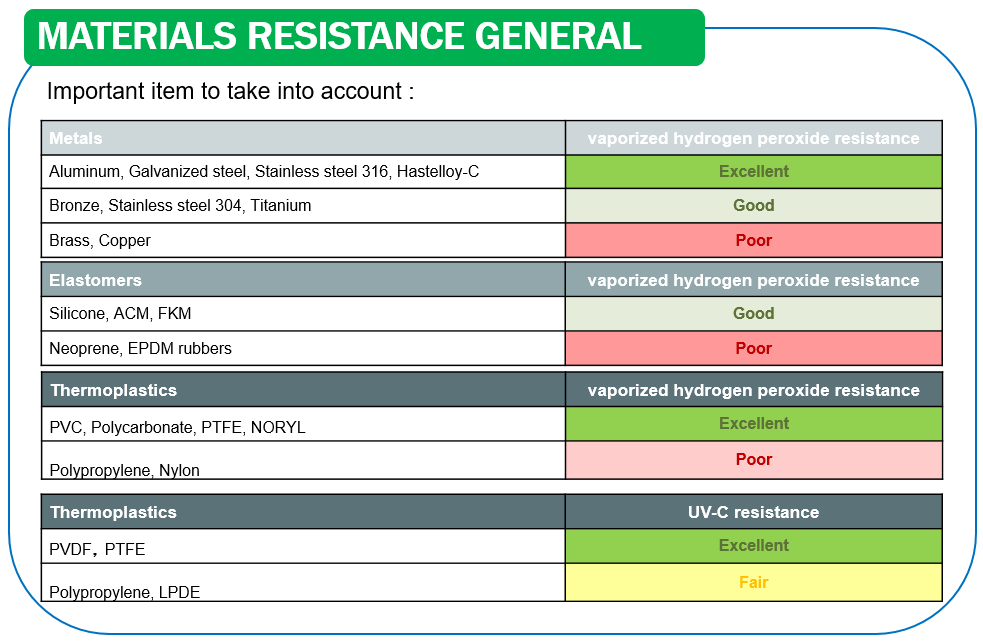

The evaluation of the impact of any substances with regards to materials is always needed in order to evaluate the level of resistance and the level of compatibility.

In addition, any application of these guidelines for the fire protection system has been excluded considering the temporary unavailability of the fire extinguishing system during the sanitization and the necessity to disable a safeguarding system.

Ozone application example

Since the discovery of its oxidizing property, ozone has been used as a bactericidal, fungicidal and inactivating agent for viruses.

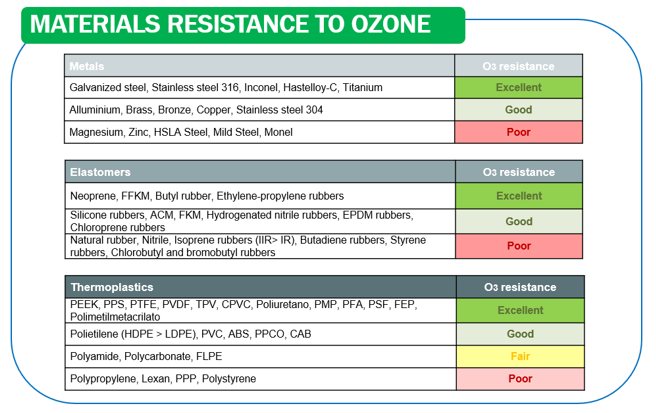

One of the key focuses is the proper use of the ozone with correlation to thermoplastic, metals and elastomers transport interiors items. This would avoid any change of material’s properties.

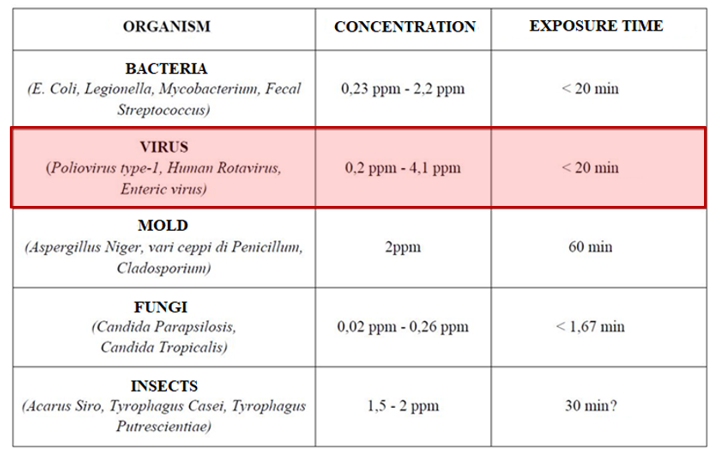

In the table below are highlighted the main features:

Sanitization exposure time for Ozone is short. It can be split between Regular Sanitization (overall duration max 25min.) and Light Sanitization (overall duration max 15min).

The application involves the administration of ozone conveyed through the transport. It takes place with detailed measures and precise methods providing rigorous schedule of administration and recovery, after verifying the absence of passengers or staff inside the trainsets.

Ozone material impacts

One of the key focus is the proper use of the ozone with correlation to thermoplastic, metals and elastomers transport interiors items. This would avoid any change of material’s proprieties.

Hereinafter a table showing the different material response to the ozone:

The system will be used in closed-cycle process, representing the sanitization and subsequent restoration of the standard environmental parameters. This aims at deleting any environmental harm of ozone dispersion into the surrounding environment.

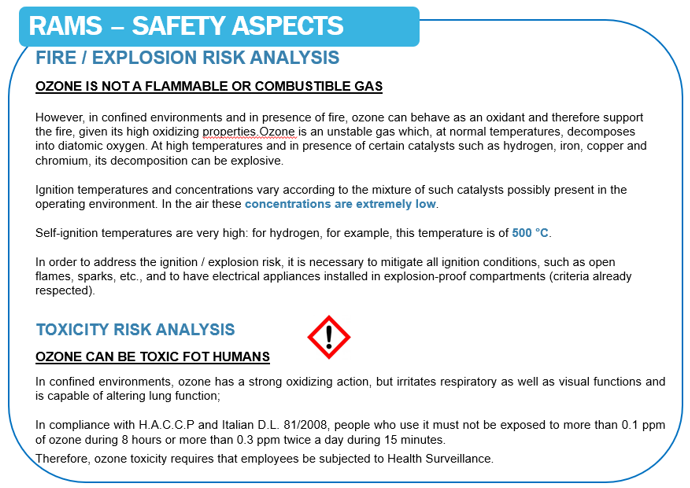

Ozone rams – safety aspects

Reliability, Availability, Maintainability and Safety (RAMS) analysis are aimed “to ensure the proper action of the system, its proper function, the ability to operate a proper maintenance within an acceptable time and the absence of damage to humans and to the environment in case of malfunction.”

The safety impacts of the application of this method can be summarized as below:

Conclusions

We are currently studying the different technical approaches, focusing on the following strong points:

- The revamping, using the pre-existing onboard system, enables a fast implementation and a reduction of the costs;

- The use of these guidelines sets the stage for equipping transports with all necessary health and sanitary regulation precautions, which will have to become routine tasks and mandatory level prevention for human health;

- The automatic system facilitates the performance of sanitization activities.

In this objective, AYES can rely on years of consolidated experience in designing and testing sub-systems for the transportation industry. In parallel we also count on numerous successful references in retrofit projects.

If you are an engineer wishing to collaborate on this project, or a stakeholder from one of these sectors of concern, feel free to contact us!

Sanitization with H202 V-Form

What is Hydrogen peroxide?

This substance was discovered in 1818 by Thénard and is found naturally in milk, honey, and ordinary tissues of normal cell function. Hydrogen peroxide kills by oxidation that occurs when an atom loses electrons.

Advantages: High efficacy, Rapid activity, Monitoring capability, Low cost.

Limitations: Material compatibility, Penetrability, Toxicity, Technique Sensitive, Storage.

The advantages of H2O2 are its relatively efficient application. It’s controllable usage and residue-free decomposition a give it a positive environmental balance and its chemical properties make it a powerful decontaminant.

Potential risk is that contact with increased concentrated levels of H2O2 can lead to skin burns and is particularly harmful when inhaled as vapour, which can lead to long-term damage to the respiratory organs. All these disadvantages and risks must be considered. Limit of exposure is 1ppm in the short term.

Overall good compatibility with all materials used in train interior: this helps the product to maintain a perfect functionality during all product life.

Sanitization with UV-C

UV light is a concrete alternative to chemical disinfection products.

Ultraviolet (UV) light decontamination system is a novel technology that may supplement standard cleaning practices and potentially further reduce the transmission of pathogens.

UV light covers a wavelength spectrum from 100 to 380 nm and is subdivided into three regions by wavelength: UVA (320 to 400 nm), UVB (280 to 320 nm), and UVC (200 to 280 nm). Among them, UVC has the strongest germicidal effect and is widely used in the form of mercury lamps to disactivate microorganisms.

The radiation warps the structure of the pathogen’s genetic material and prevents the viral particles from making more copies of themselves.

To achieve maximal efficacy, it is suggested that UV light devices should be utilised in multiple locations within public transportation. To ensure staff and patient safety, it is recommended that all personnel should be cleared from the room before use and that the room be closed to entry for the duration of the UV light application.

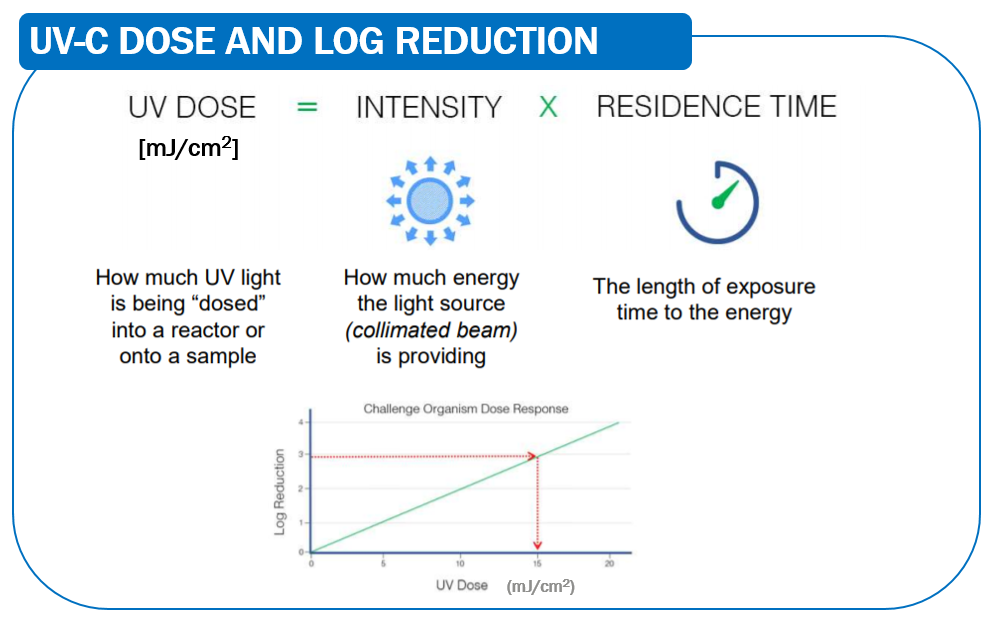

UVC light, when used in appropriate environments and according to UV-C dose & log reduction, can reduce the growth of the coronavirus and take the pressure off employees who currently disinfect rooms and surfaces manually.

To complete a discussion about innovative systems of sanitization special attention must also be given to other forms of sanitization. Such a strategy should provide for the following treatments:

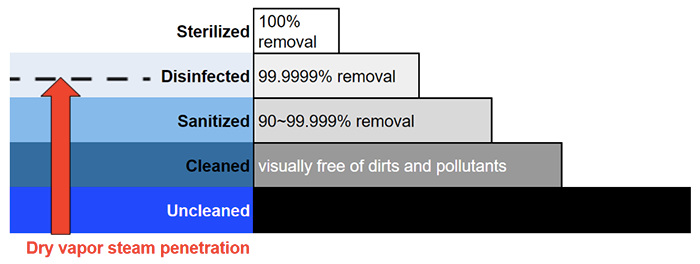

Sanitization with Dry Vapor Steam

Using temperatures of 80 °C (176 °F) or higher on contact surfaces is known to remove most bacteria and inactivate most viruses. With extended exposure times from a few seconds to 30 minutes (depending on the pathogen) even at 60 °C (140 °F), temperature is able to remove or inactivate pathogens.

The World Health Organization recognizes viral inactivation by heat and recommends boiling drinking water in regions where communicative diseases are common.

Dry vapor steam is proven to both clean and sanitize and is capable of disinfecting in controlled environments where lethal temperatures can be guaranteed.

Electrostatic Spray Technology

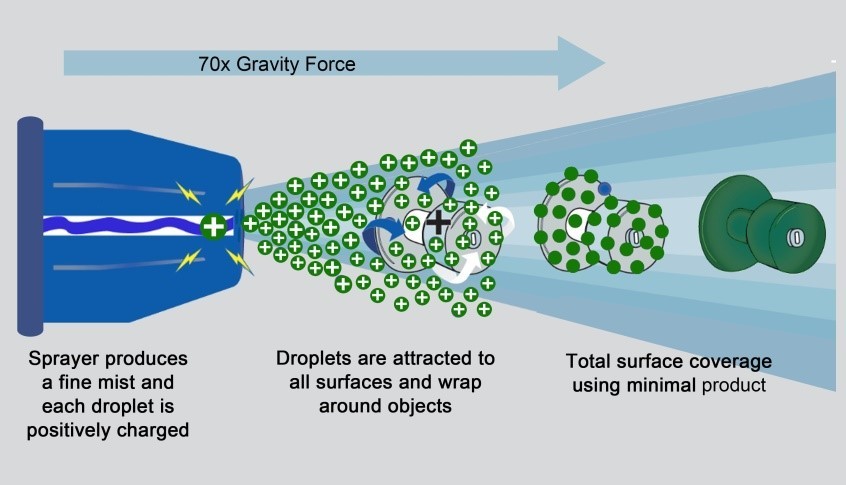

Electrostatic spray technology is a new way to apply cleaners, sanitizers, and disinfectants to help facilities treat surfaces, often in less time and with better coverage than traditional cleaning methods. Air and liquid enter the rear of the nozzle separately. The air moves through the nozzle under pressure and meets the liquid at the nozzle tip, causing the formation of spray droplets that are 30 to 60 microns in diameter. At the tip of the nozzle is a tiny electrode which applies an electrical charge to the spray.

The electrical charging causes a natural force of attraction between the spray droplets and target surface, similar to the attraction between items of clothing created by the tumbling of a clothes dryer.

Finally, to account for the blind spots where a standard system is not able to provide a high level of sanitization, it would be advantageous to use a COMBINED ACTION of the above described treatments.

For instance, South Korea has been using dry vapour steam in conjunction with sodium hypochlorite based chemical treatments in disinfecting “phone booth-style” COVID-19 testing stations inside hospitals.

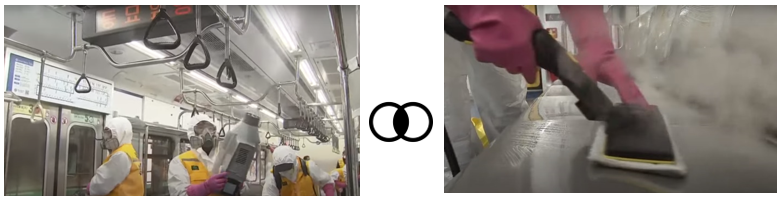

Seoul Metro has been disinfecting subway trains with hydrogen peroxide based electrostatic misting systems and dry vapour steam for upholstery and human contact surfaces.

Conclusions

AYES is investing in exploring new options as large scale cleaning and disinfecting treatments are necessary. We are strongly committed to finding innovative ways to contribute to improving the sanitization and treatments applications for public transportation.

Coronavirus survival on surfaces

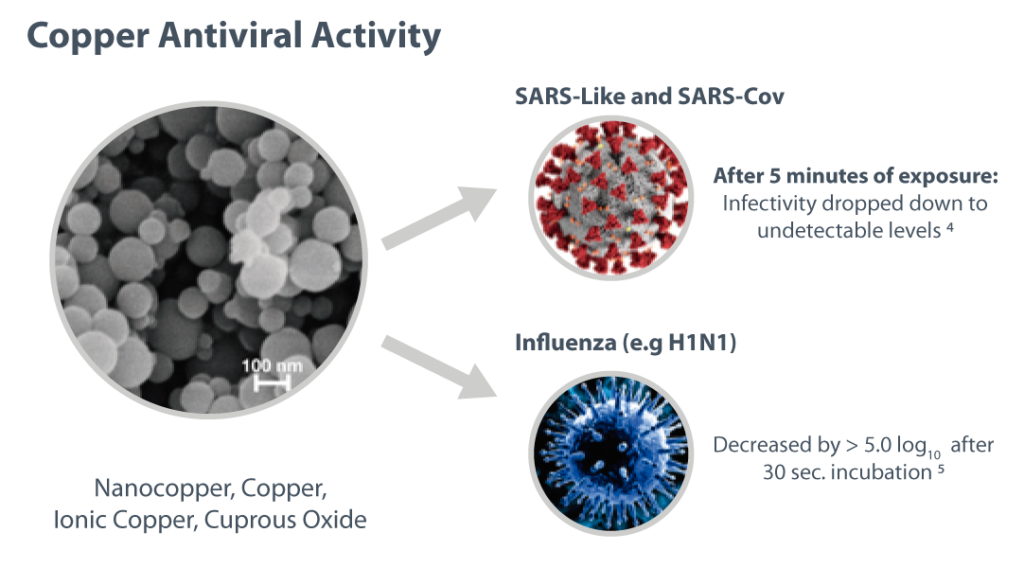

Studies reveal that while the virus is still present on plastic and stainless steel after a 72-hour period, it is no longer detectable after 24 hours on cardboard and after 4 hours on copper.

Antiviral coating

Antiviral coating may represent a new form of protection against Covid-19. Already used in Hong-Kong, it is a non-toxic material reportedly safe for the skin as well as for the environment. Moreover, it can be applied onto surfaces that are frequently touched like handrails as well as on surfaces inside trains, metros and buses.

The substance works through millions of nanocapsules that contain disinfectants (unlike common disinfecting methods such as diluted bleach and alcohol).

Nanoparticles

Nanoparticles of different materials such as metal nanoparticles, carbon nanotubes, metal oxide nanoparticles, and graphene-based materials have demonstrated enhanced antimicrobial and antiviral capacity. The use of inorganic nanomaterials (compared with organic antimicrobial agents) is best due to their robustness and long shelf life. At high temperatures/pressures, inorganic antimicrobial materials are found to be more stable than organic antimicrobial agents.

Multilevel antimicrobial polymer (map-1)

Effective in killing viruses, bacteria and even hard-to-kill spores, MAP-1 can deactivate up to 99.9% of highly infectious viruses such as measles, mumps and rubella. It also deactivates 99.99% of the surrogate Feline CaliciVirus (FCV) – a gold standard for disinfection efficiency since FCV is proven to be more resistant than coronaviruses.

This spray is heat sensitive: when somebody touches it, the polymer material can “feel” the temperature increase from the body heat and will release the disinfectant. Once the hand is removed, it will close and conserve the remaining disinfectant.

Copper

The ions in copper alloys have both antiviral and antibacterial properties. They can kill over 99.9% of bacteria within a 2-hours timeframe. Copper is even more effective than silver, which requires moisture to activate its antimicrobial properties.

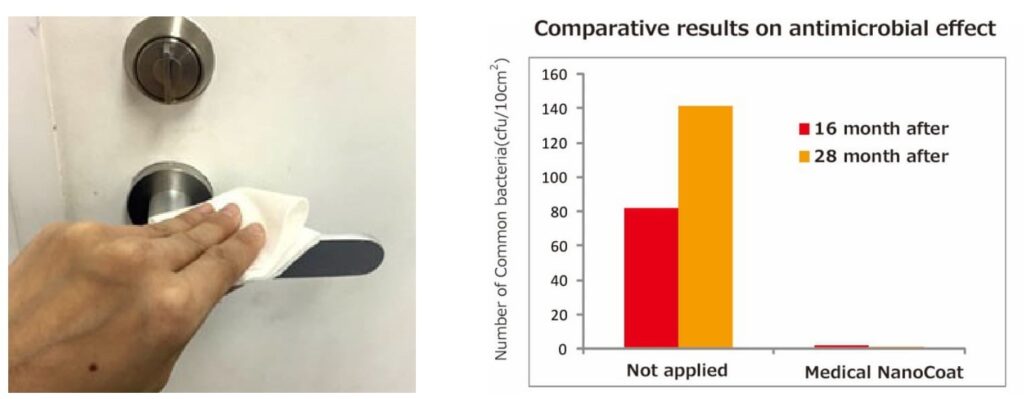

Nanocoating surface

Nanocoating can show up to 99.9998% effectiveness against bacteria, formaldehyde, mold and viruses and is up to 1.000 times more efficient than previous technologies available on the market. It could represent a helpful means of controlling the future spread of the epidemic.

Conclusion

This new smart antiviral material could represent a leg up in the fight against Coronaviruses. The research team claims it actively kills bacteria and viruses on surfaces for up to 90 days and can be applied on a wide range of surfaces, including metals, plastics and fabrics.

AYES regards this not only as a potential breakthrough in the fight against COVID-19 but also as an important step towards defining effective global strategies to fight known and yet unknown viruses and bacteria.